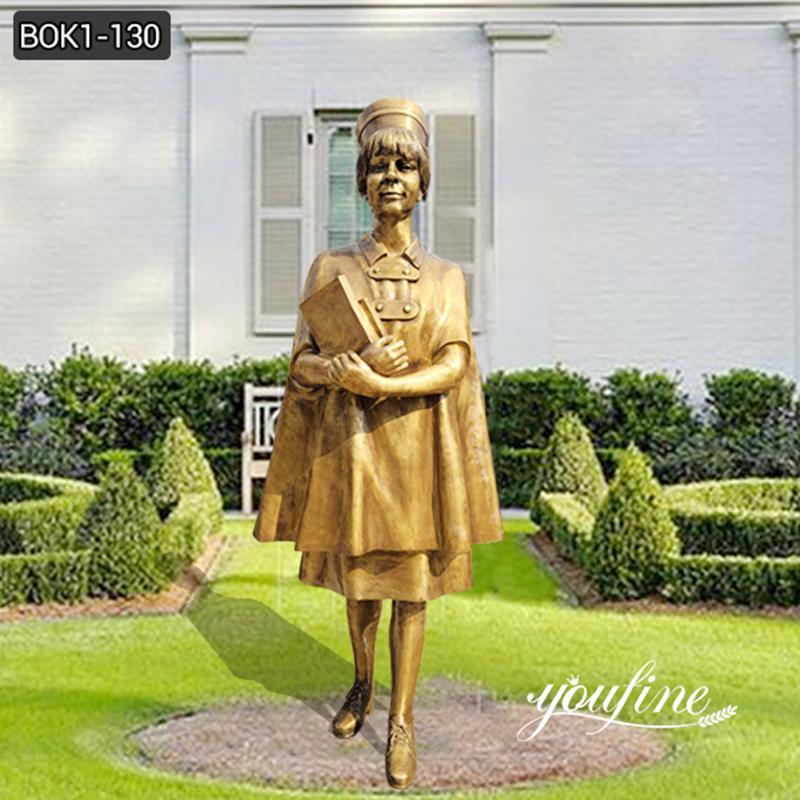

Details of Custom Bronze Statues:

Our client asked us to do a custom nurse sculpture. He said the nurse sculpture was a tribute to some hard-working nurses during COVID-19. So the figure height is also very realistic, about 5″6′. This custom bronze statue is installed in a hospital in Boston. If you are in Boston, you may have a chance to see our sculpture for yourself.

Production Process:

1- Confirm the Design

First of all, our 3D model is built according to the customer’s picture. Second, our client asked us to add the cape to the original design and change the kind of nurse hat. So our designers made drawings according to customer’s requirements.

2- Clay Mold

When the client confirms the design, our artists start to prepare the clay material and internal structure. Our artists make molds out of clay based on design photos. The journey from unformed clay to character formation is very difficult and great.

So they modified the mold again and again to achieve a 95%-plus similarity to the design. There is no doubt that our clay molds look real, so our customers confirmed and recognized our work right away.

3- Lost Wax Method

When the clay model is finalized, our artist goes to the next step. The next step is to cast bronze. This process involves about 33 procedures. This process is very difficult and demanding. We must use our most professional masters to do it. Of course, our artists are highly experienced and grew up learning the traditional lost wax method of casting bronze custom sculptures. Therefore, the appearance of our sculptures is very delicate and beautiful.

4 – Patina

After welding and polishing, our master would do the patina. As you could clearly see, this color is difficult to handle. Because the nurse’s color is not pure brown or gold, but a mixture. So our artist did this color three times or so. Ultimately, the appearance of the sculpture reaches a perfect true color. Our customers love it very much.

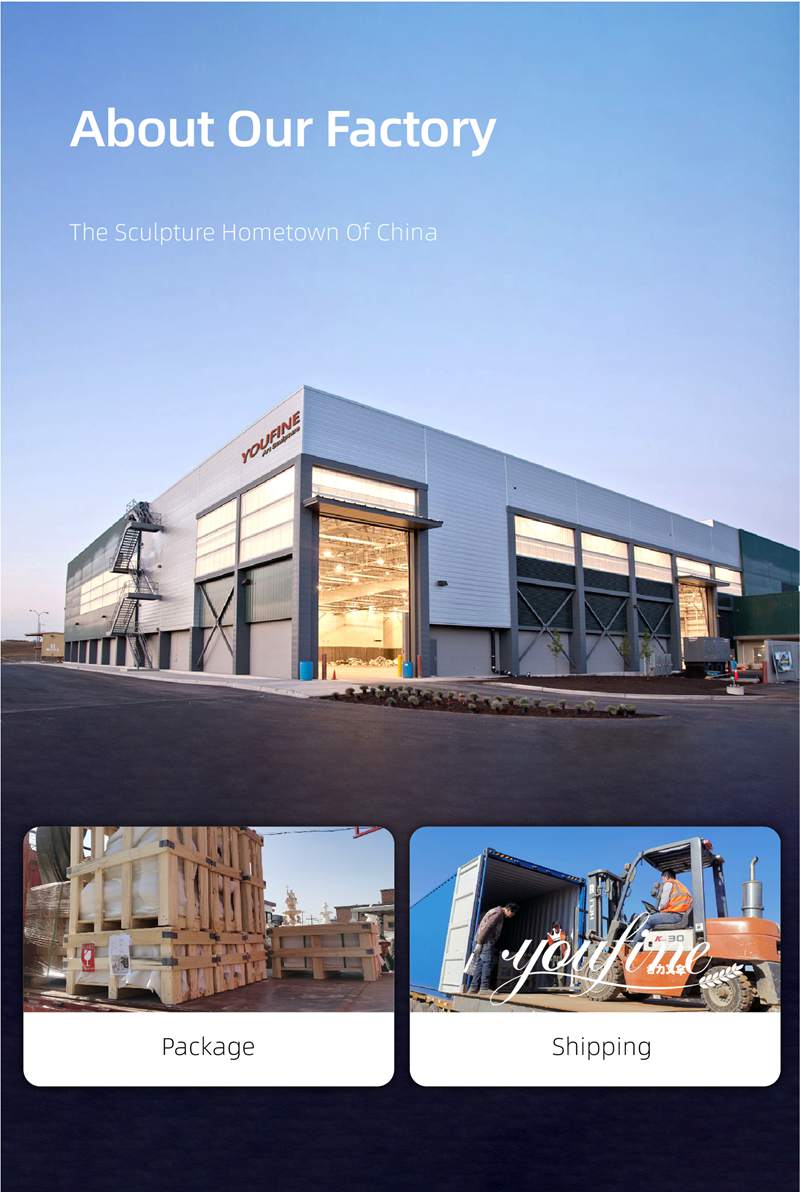

Silica Sol Precision Casting Method:

Our factory has been using an advanced silica sol precision casting method. The biggest difference between the silica sol investment casting method and the traditional casting method is that in the traditional method, the bronze liquid is surrounded by ammonia water. But ammonia is not as stable as silica sol.

Therefore, if there is no silica sol investment casting method, some white spots and textures would appear on the surface of the bronze sculpture after 1-3 years. But our bronze statues could stand for more than 100 years without any white spots and textures.

We could produce any type of bronze custom sculpture, from life-size to oversized statues, including busts or other unique designs. We could ship our statues anywhere in the world. So please contact us below and we would be happy to assist you.